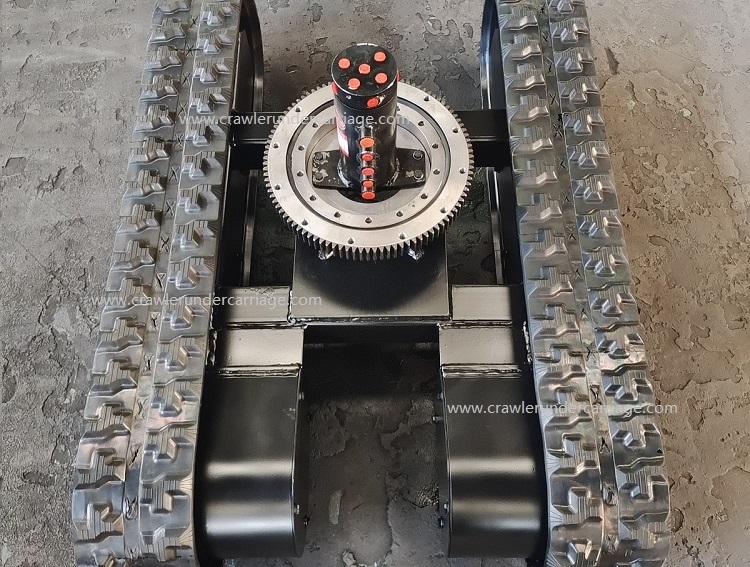

Chassis ea ka tlas'a koloi e nang le sesebelisoa se potolohangke e 'ngoe ea meralo ea mantlha bakeng sa liepa ho fihlela ts'ebetso e sebetsang hantle le e tenyetsehang. E kopanya sesebelisoa se kaholimo sa ts'ebetso (boom, stick, bakete, jj.) ka tlhaho le mokhoa o ka tlase oa ho tsamaea (lipina kapa mabili) 'me e nolofalletsa ho potoloha ka 360° ka har'a sistimi ea slewing bearing le drive, ka hona e atolosa sebaka sa ts'ebetso haholo. Se latelang ke tlhahlobo e qaqileng ea lits'ebetso le melemo ea eona e ikhethang:

I. Sebopeho sa Sebopeho sa Lebenkele la ka tlas'a koloi le potolohang

1. Ho bea Rotary

- Li-bearing tse kholo tsa bolo kapa li-roller tse hokahanyang foreimi e ka holimo (karolo e potolohang) le foreimi e ka tlase (chassis), matla a axial a jereng, a radial, le linako tsa ho phethola.

- Mefuta e tloaelehileng: li-bearing tsa bolo tse nang le lintlha tse 'ne tsa mola o le mong (tse bobebe), li-bearing tsa li-roller tse tšetsoeng (tse boima).

2. Sistimi ea ho Tsamaisa ea Rotary

- Motlakase oa haeteroliki: o khanna gear ea rotary bearing ka har'a reducer ho fihlela potoloho e boreleli (tharollo e tloaelehileng).

- Enjene ea motlakase: e sebelisoa liepeng tsa motlakase, e fokotsa tahlehelo ea haeteroliki le ho fana ka karabelo e potlakileng.

3. Moralo oa Kamore e ka Tlas'a Koloi e Matlafalitsoeng

- Foreimi ea ka tlas'a seketsoana sa tšepe e matlafalitsoeng ho netefatsa ho tiea le botsitso nakong ea ho slew.

- Kariki e ka tlase ya mofuta wa terene hangata e hloka tekanyo e pharaletseng ya terene, athe tjhese ya mofuta wa thaere e hloka ho hlomelloa ka di-outrigger tsa hydraulic ho leka-lekanya motsotso wa ho slewing.

II. Lintlafatso tsa Bohlokoa Tshebetsong ea Baepolli

1. Ho tenyetseha ha Ts'ebetso

- 360° Ts'ebetso e sa sitisoeng: Ha ho hlokahale hore ho tsamaiswe chassis ho koahela libaka tsohle tse potolohileng, e loketse libaka tse moqotetsane (joalo ka kaho ea litoropo, ho epolloa ha liphaephe).

- Ho Beha Sebaka ka Nepahalo: Taolo e lekanang ea li-valve ea lebelo la ho slewing e nolofalletsa ho beha bakete boemong ba milimithara (joalo ka ho qeta mokoti oa motheo).

2. Ntlafatso ea Bokhoni ba Mosebetsi

- Makgetlo a Fokoditsweng a ho Tsamaya: Di-excavator tsa letsoho le tsitsitseng tsa setso di hloka ho fetola maemo kgafetsa, ha tjhase ya ka tlasa koloi e potolohang e ka fetola difahleho tse sebetsang ka ho potoloha, e leng se bolokang nako.

- Liketso tse Kopantsweng tse Kopantsweng: Taolo ya kgokelo ya ho slewing le boom/stick (jwalo ka diketso tsa "ho swing") e ntlafatsa bokgoni ba tshebetso ya potoloho.

3. Botsitso le Polokeho

- Setsi sa Taolo ea Matla a Khoheli: Mejaro e matla nakong ea ho slewing e ajoa ka tlas'a koloi, 'me moralo oa boima bo khahlanong le boima o thibela ho phethoha (joalo ka boima bo khahlanong le boima bo kentsoeng ka morao ho li-excavator tsa merafo).

- Moralo o Thibelang ho thothomela: Ho se tsitse ha koloi e thiba ho thibelwa ke ho thiba ha koloi e ka tlase ho koloi, ho fokotsa tshusumetso ya sebopeho.

4. Katoloso ea Mesebetsi e Mengata

- Mekhahlelo ea phetoho e potlakileng: Chassis ea ho slewing e lumella ho nkeloa sebaka ka potlako ha lihokelo tse fapaneng (joalo ka lihamore tsa hydraulic, li-grab, jj.), ho ikamahanya le maemo a fapaneng.

- Ho kopanngoa ha Lisebelisoa tse Thusang: Tse kang mela ea hydraulic e potolohang, lihokelo tse tšehetsang tse hlokang ho potoloha ho tsoelang pele (joalo ka li-auger).

III. Maemo a Tloaelehileng a Tšebeliso

1. Libaka tsa Kaho

- Ho phethela mesebetsi e mengata e kang ho epa, ho kenya thepa le ho e lekanya sebakeng se fokolang, ho qoba ho sisinyeha khafetsa ha chassis le ho thulana le litšitiso.

2. Merafo

- Mechini e meholo e chekiloeng ka lithane tse kholo e nang le chassis e matla ea ho slew ho mamella ho chekoa ha mojaro o boima le ho potoloha ho tsoelang pele ha nako e telele.

3. Pholoso ea Maemo a Tšohanyetso

- Ho seha ka potlako ho lokisa tsela eo mosebetsi o etsoang ka yona, ho kopantswe le ho tshwara kapa ho seha dikere ho tlosa ditshila.

4. Temo le Meru

- Sekoahelo se potolohang se thusa ho tshwara le ho bokella patsi kapa ho cheka dikoti tsa difate ka botebo.

IV. Mekhoa ea Ntshetsopele ea Theknoloji

1. Taolo e Bohlale ea Rotary

- Ho beha leihlo sekhutlo se potolohang le lebelo ka IMU (Inertial Measurement Unit), ho thibela ka bohona liketso tse kotsi (joalo ka ho thiba matsoapong).

2. Sistimi ea ho Potoloha ha Matla a Motsoako

- Lienjene tsa motlakase tse potolohang li khutlisa matla a ho brake, li fokotsa tšebeliso ea mafura (joalo ka Komatsu HB365 hybrid excavator).

3. Tekanyo ea Boima bo Bobebe le ho Tšoarella

- Ho sebedisa tshepe e matla haholo kapa thepa e kopaneng ho fokotsa boima ba ka tlasa koloi ha o ntse o ntlafatsa ho kwalwa ha bearing e potolohang (e thibelang lerole, e thibelang metsi).

V. Lintlha tsa Tlhokomelo

- Ho tlotsa bearing e potolohang kamehla: Ho thibela ho senyeha ha tsela ea raceway ho bakang lerata kapa ho thothomela ha koloi e ka tlas'a koloi.

- Hlahloba ho jara bolte pele: Ho lokollwa ha dibolte tse hokahanyang bearing ya ho slewing le chassis ho ka baka dikotsi tsa sebopeho.

- Ela hloko bohloeki ba oli ea hydraulic: Tšilafalo e ka lebisa tšenyo ea enjene e potolohang 'me ea ama ts'ebetso ea ho khanna ka tlas'a koloi.

Kakaretso

Chassis ea ka tlas'a koloi e nang le mokhoa o potolohang ke moralo o ikhethang o khethollang li-epillara ho mechini e meng ea kaho. Ka mokhoa oa "ka tlas'a koloi e tsitsitseng le 'mele o ka holimo o potolohang", e fihlella mokhoa o sebetsang hantle, o tenyetsehang le o sireletsehileng oa ts'ebetso. Nakong e tlang, ka ho kenella ha motlakase le mahlale a bohlale, ka tlas'a koloi e potolohang e tla tsoela pele ho ea paballong ea matla, ho nepahala le ho tšoarella, e be sehokelo sa mantlha ntlafatsong ea theknoloji ea li-epillara.

Mohala:

Mohala: Imeile:

Imeile: