rubber steel tracked undercarriage system manufacturers for drilling rig mobile crusher

Product Description

One of the main advantages of a tracked undercarriage is its ability to provide excellent traction and stability. The track system allows the machine to distribute its weight over a larger surface area, reducing ground pressure and preventing it from sinking into soft or uneven terrain. This makes track-equipped machinery ideal for working on muddy, wet or rough surfaces, where wheeled machinery may be difficult to maneuver effectively.

The tracked undercarriage enhances the machine's ability to travel on steep slopes and slopes. The grip provided by tracks allows the machine to climb hills more easily and safely than wheeled vehicles. This makes machines equipped with crawlers ideal for situations such as earthmoving, forestry and construction where working on hilly or uneven terrain is possible.

Quick Details

| Condition | New |

| Applicable Industries | Mobile Cruher |

| Video outgoing-inspection | Provided |

| Place of Origin | Jiangsu, China |

| Brand Name | YIKANG |

| Warranty | 1 Year or 1000 Hours |

| Certification | ISO9001:2019 |

| Load Capacity | 20 – 150 Tons |

| Travelling Speed (Km/h) | 0-2.5 |

| Undercarriage Dimensions(L*W*H)(mm) | 3805X2200X720 |

| Width of Steel Track(mm) | 500 |

| Color | Black or Custom Color |

| Supply Type | OEM/ODM Custom Service |

| Material | Steel |

| MOQ | 1 |

| Price: | Negotiation |

Composition Of Crawler Underframe

Mobile Steel Track Undercarriage Advantages

1. ISO9001 quality certificate

2. Complete track undercarriage with steel track or rubber track, track link , final drive, hydraulic motors, rollers, crossbeam.

3. Drawings of track undercarriage are welcome.

4. Loading capacity can be from 20T to 150T.

5. We can supply both rubber track undercarriage and steel track undercarriage.

6. We can design track undercarriage from customers’ requirements.

7. We can recommend and assemble the motor & drive equipment as customers’ requests. We can also design the whole undercarriage according to special requirements, such as measurements, carrying capacity, climbing etc. which facilitate the customers’ installation successfully.

Parameter

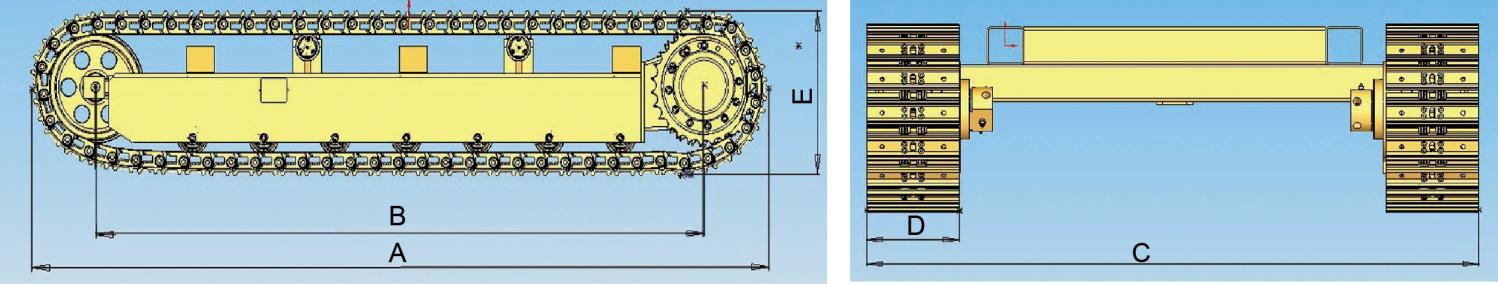

|

Type |

Parameters(mm) |

Track Varieties |

Bearing(Kg) |

||||

|

A(length) |

B(center distance) |

C(total width) |

D(width of track) |

E (height) |

|||

|

SJ2000B |

3805 |

3300 |

2200 |

500 |

720 |

steel track |

18000-20000 |

|

SJ2500B |

4139 |

3400 |

2200 |

500 |

730 |

steel track |

22000-25000 |

|

SJ3500B |

4000 |

3280 |

2200 |

500 |

750 |

steel track |

30000-40000 |

|

SJ4500B |

4000 |

3300 |

2200 |

500 |

830 |

steel track |

40000-50000 |

|

SJ6000B |

4500 |

3800 |

2200 |

500 |

950 |

steel track |

50000-60000 |

|

SJ8000B |

5000 |

4300 |

2300 |

600 |

1000 |

steel track |

80000-90000 |

|

SJ10000B |

5500 |

4800 |

2300 |

600 |

1100 |

steel track |

100000-110000 |

|

SJ12000B |

5500 |

4800 |

2400 |

700 |

1200 |

steel track |

120000-130000 |

|

SJ15000B |

6000 |

5300 |

2400 |

900 |

1400 |

steel track |

140000-150000 |

Application Scenario

YIKANG complete undercarriages are engineered and designed in many configurations to serve a wide range of applications.

Our company designs, customizes and produces all kinds of steel track complete undercarriage for loads of 20 tons to 150tons. Steel tracks undercarriages are suitable for roads of mud and sand, stones rock and boulders , and steel tracks are stable on every road.

Compared with rubber track, rail has abrasion resistance and little risk of fracture.

In summary, the ability of undercarriage manufacturers to customize tracked undercarriages offers many advantages to industries that rely on heavy machinery. From improved performance and adaptability to cost savings and compliance, the benefits of customization are clear. As the industry continues to evolve and the requirements for equipment become higher and higher, the ability to customize tracked chassis will play a vital role in meeting these needs.

Packaging & Delivery

YIKANG track undercarriage packing: Steel pallet with wrapping fill, or Standard wooden pallet.

Port: Shanghai or custom requirements

Mode of Transportation: ocean shipping, air freight, land transportation.

If you finish the payment today, your order will ship out within the delivery date.

| Quantity(sets) | 1 - 1 | 2 - 3 | >3 |

| Est. Time(days) | 20 | 30 | To be negotiated |

One- Stop Solution

Our company has a complete product category which means you can find everything you need here. Such as track roller, top roller, idler, sprocket, tension device, rubber track or steel track etc.

With the competitive prices we offer, Your pursuit is sure to be a time-saving and economic one.