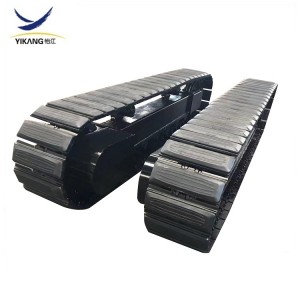

Customizing heavy-duty equipment steel track undercarriage

►►►Since 2005

Crawler Tracked Undercarriages

Manufactuer In China

- ►20 years manufacturing experience, reliable product quality

- ►Within one year of purchase, non-man-made failure, free original spare parts.

- ►24-hour after-sales service.

- ►High configuration,high efficiency,global service, custom design.

Are your mechanical equipment currently encountering these walking problems?

Question 1: Insufficient load-bearing capacity, track undercarriage prone to deformation?

We use high-strength alloy steel. The motor and tracks are selected and designed according to the load capacity of your machine to ensure that the core load-bearing components of the crawler undercarriage are sturdy and durable, with a 50% increase in carrying capacity.

Question 2: The terrain is complex and has poor passability, making it prone to vehicle getting stuck?

YIJIANG tracked undercarriage, optimized ground contact pressure and large torque drive system, endows the equipment with outstanding off-road and traversing capabilities, enabling it to easily handle muddy, sandy and inclined terrains.

Question 3: The standard track undercarriage cannot meet the requirements of non-standard equipment?

YIJIANG company can provide in-depth support for customized non-standard products. Based on the size, weight, center of gravity and working conditions of your equipment, a personalized design is carried out to achieve a perfect match.

Question 4: Frequent maintenance, troublesome replacement of spare parts?

YIJIANG can offer modular design and long-life sealing systems, with simple maintenance and comprehensive support for spare parts supply, effectively reducing downtime.

Rooted in professionalism, achieving reliability - Our core principle is quality first and service first.

Outstanding Load-bearing Capacity and Durability

The core structural components of the YIJIANG track undercarriages are made of high-strength steel of grade Q345B or above. Through finite element analysis, the stress distribution has been optimized, and the fatigue life exceeds the industry standards.

Precise driving and walking system

Equipped with hardened sprocket, track roller and high-maintenance wear-resistant track pads, this parts have high transmission efficiency, minimal wear and smooth operation.

Comprehensive Customization Capability

YIJIANG offers full customization options for track gauge, length, height, installation interface, etc., and can integrate hydraulic and motor power systems.

Skilled welding and manufacturing techniques

Welding ensures the consistency of the weld seams. For critical weld seams, non-destructive testing (UT/MT) is carried out to ensure the structural safety.

Widely Applied to Various Types of Heavy Mobile Equipment in Various Fields

Construction Machinery - for small excavators, drilling machines, rotary drilling rigs, mobile crusher, aerial work platforms, exploration, mini piling machinery, loading equipment, etc.

Steel track for mobile crusher

Rubber pads for drilling rig

Rubber track for excavator

Agricultural Machinery - for sugarcane harvesters, spraying machines, etc.

Triangular tracked chassis for sugar cane harvester

Rubber track for orchard spary equipment

Rubber track for garden harvester

Special Vehicles - for forest logging machines, snowmobiles, swamp vehicles. Rescue Equipment

Rubber track for Special Vehicles

Steel track for recovery vehicle

Rubber track for fire-fighting robot

Customized Process and Service Assurance

From conception to reality, we work hand in hand with you to realize your dreams.

Process steps:

Requirement communication: You provide equipment parameters and working conditions requirements.

Requirement communication: You provide equipment parameters and working conditions requirements.

Scheme design: Our engineers conduct structural design and simulation.

Scheme design: Our engineers conduct structural design and simulation.

Scheme confirmation: Review the scheme, parameters and quotation together with you.

Scheme confirmation: Review the scheme, parameters and quotation together with you.

Production manufacturing: Use advanced techniques and strict quality inspection.

Production manufacturing: Use advanced techniques and strict quality inspection.

Delivery and acceptance: Deliver on time and provide installation and commissioning guidance.

Delivery and acceptance: Deliver on time and provide installation and commissioning guidance.

Service Guarantee

Quality assurance: Provide a 12-month warranty period.

Quality assurance: Provide a 12-month warranty period.

Technical support: Provide lifetime technical consultation.

Technical support: Provide lifetime technical consultation.

Part supply: Ensure long-term stable part supply.

Part supply: Ensure long-term stable part supply.

What are the Customer's Machines?

Twenty years of dedicated efforts, solely aimed at creating a more reliable crawler tracked undercarriage walking system.

We help many clients create perfect machine equipment. When the machine equipment successfully starts working, it is our proudest moment.

How We Ensure The Quality Of Crawler Track Undercarriage

Our rigorous production process from the selection of materials to every aspect of production.

We are factory direct sales, from consumers to stores to wholesalers to agents to general distributors to factory merchants, choose us to save a lot of intermediate links, to bring you the maximum profit margin!

Reply your inquiry in 24 working hours

Our product: insist on quality first the production standard support factory and products inspection

Our service: perfect after-sales service and professional team

Company strength: Short lead time and fast delivery flexible payment terms

Exclusive and unique solution can be provided to our customer by well-trained and professional engineers and taffs

One-stop solution a complete category includes all that you need

About YIJINAG

Zhenjiang Yijiang’s undercarriage is composed of track roller、top roller、idler、sprocket、tension device rubber track or steel track etc, it is manufactured with the latest domestic technology, featuring compact structure, reliable performance, durability, convenient operation and low energy consumption. It is widely used in various drilling, mine machinery, fire-fighting robot, underwater dredging equipment ,aerial working platform, transport lifting equipment, agricultural machinery, garden machinery, special working machinery, field construction machinery, exploratory machinery, loader, static detection machinery, gadder , anchor machinery and other large, medium and small machinery.

Yijiang's Exhibition

COMMON QUESTIONS

Most Popular Questions

We have listed some questions you may ask. If you have more inquiries about our products, you can send an inquiry to contact us.

Q1. If your company a trader or manufacturer?

A : We are the manufacturer & trader .

Q2. Can you supply customize undercarriage?

A : Yes. We can customize the undercarriage according to your requirements.

Q3. How is your price?

A : We guarantee the quality while providing the right price for you.

Q4. How is your after – sale service?

A : We can give you one year after sales warranty, and any quality problem caused by manufacturing defects can be unconditionally maintained.

Q5. What is your MOQ?

A : 1 set.

Q6. How will you place your order?

A : In order to recommend a suitable drawing and quotation to you , we need to know:

a. Rubber track or steel track undercarriage, and need the middle frame.

b. Machine weight and undercarriage weight.

c. Loading capacity of the track undercarriage ( the weight of the whole machine excluding of track undercarriage.

d. Undercarriage’s length, width and height

e. Track’s Width.

f. Height

g. The max speed (KM/H).

h. Climbing slope angle.

i. The machine’s apply range , working environment.

j. Order quantity.

k. Port of destination.

l. Whether you require us to purchase or collocate relevant motor and gear box or not, or other special request.

● The working environment and intensity of the equipment.

●The load capacity and working conditions of the equipment.

●The size and weight of the equipment.

●Maintenance and upkeep costs of tracked undercarriage.

●A steel track undercarriage supplier with reliable brands and good reputation.

- First, decide which kind of undercarriage best suits the requirements of the equipment.

- Selecting the proper undercarriage size is the second step.

- Thirdly, think about the chassis's construction and material quality.

- Fourth, be mindful of the chassis's lubrication and upkeep.

- Select suppliers who offer strong technical assistance and after-sale service.

- You can make the payment to our bank account, Western Union or PayPal.

- 30% deposit in advance, 70% balance against the copy of B/L.

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

1. If we have stock, usually about 7 days.

2. If we don’t have stock, usually about 25-30 days.

3.If it is a customised product, depending on the customised requirements, usually 30-60 days.

Yes.

Are you still troubled by selecting a crawler undercarriage suitable for your mobile machine?

Kindly share with us about your idea of your crawler tracked undercarriage. Let’s make good things happen together !

Phone:

Phone: E-mail:

E-mail: