I-Zhenjiang Yijiang Machinery Co., Ltd

I-CrawlerIsihlalo esingaphansi kwemotoIncwadi Yokunakekela

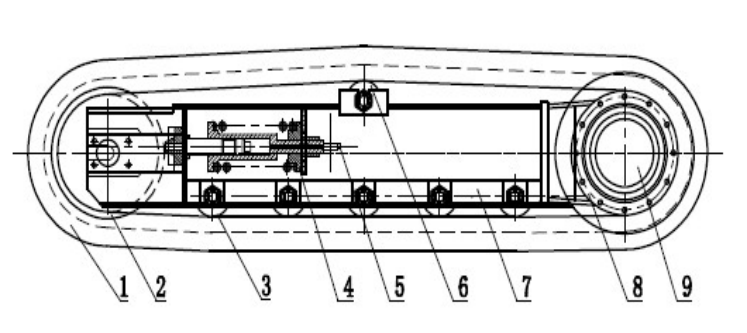

1. ukuhlanganiswa kwethrekhi 2. IDLER3. i-track roller 4. idivayisi yokucindezela 5. indlela yokulungisa intambo 6.I-ROLLER ENGAPHEZULU7. uhlaka lwethrekhi 8. isondo lokushayela 9. isinciphisi sejubane lokuhamba (igama elivamile: ibhokisi lesinciphisi sejubane lemoto)

Imizila yesobunxele nesokudla iqhutshwa yizinjini ze-hydraulic ezihambayo kwesobunxele nakwesokudla ukuze zishayele amabhokisi egiya ahambayo kwesobunxele nakwesokudla ngokulandelana, zishayele imizila ukuze zihambe.

(1)Imihlangano yethrekhi(kufaka phakathi izinsimbi zethrekhi yensimbi kanye nezinsimbi zethrekhi yerabha)

I-1:1 Ukuhlanganiswa kwethrekhi yensimbi kwenziwa ngensimbi ye-alloy enamandla aphezulu eyakhiwe ngenqubo ekhethekile yokwelapha ukushisa, equkethe ukumelana okuqinile kokuguguleka, impilo yenkonzo ende kanye namandla aphezulu.

I-1:2 Rubber Track Assembly, i-Rubber track iyibhande lerabha eliyindilinga elenziwe ngerabha elihlanganiswe ngezinto zensimbi noma zefayibha. Izinyathelo zokuqapha zokusebenzisa: umshini kufanele ugwenywe ukuqala noma ukujika ngokushesha ezindaweni ezibukhali nezivelele. Ungavumeli indawo yerabha ukuthi ithintane namafutha, sula uwoyela ngokushesha nje lapho ukhona, futhi ugweme ukuthi i-track ithintane nezinye izingxenye emshinini, ikakhulukazi emaphethelweni angaphakathi. Ungasebenzisi amasondo okushayela agugile kakhulu, kuzolimaza amazinyo ensimbi e-track. Uma umshini ungasebenzi isikhathi eside, i-track yerabha kufanele isuswe futhi ihlanzwe ukungcola nezinye izinto, kugwenywe ilanga nemvula. Njengoba kuyimikhiqizo yerabha, i-track yerabha ngokuvamile isetshenziswa emazingeni okushisa asukela ku--25° kuya ku-55°.

1:3 Ingasetshenziswa ezimbonini ezikhethekile, njengalezo ezisebenza ngaphansi kwamanzi olwandle, lapho usawoti ohlukahlukene uncibilikiswa khona futhi kukhona ama-ion ahlukahlukene, okuholela ekufakweni kwe-oxidizing kanye nokunciphisa izakhiwo. Kuyingozi kakhulu enjolobeni noma ensimbini. Njengamanje, ngaphansi kwesisekelo sokungabikho kokusekelwa kwedatha okuhambisanayo, injoloba ilandela iwaranti yesigamu sonyaka noma amahora angu-500, bese ilungiswa ngokuya ngokusetshenziswa kwesimo. Kufanele kugcizelelwe ukuthi, kungakhathaliseki ukuthi i-chassis iyinjoloba noma insimbi, kufanele ihlanzwe ngamanzi ahlanzekile ngokushesha ngemva kokuphuma emanzini olwandle!

(2)IDLER, I-TRACK ROLLE

Izimo zokusebenza ze-IDLER kanye ne-TRACK ROLLER zinzima kakhulu, azithwali nje kuphela isisindo somshini ngokuqondile, kodwa futhi zithwala umthwalo womthelela onamandla ovela epuletini lesisekelo. Ngezinye izikhathi i-TRACK ROLLER kufanele ithwale ingxenye yesisindo somshini wonke. Ngenxa yesikhundla esiphansi sokufakwa kwe-TRACK ROLLER, ibilokhu isematsheni nase-magma isikhathi eside, futhi ingase iguge kakhulu. Ngakho-ke, izindawo zokusebenza ze-track roller, i-IDLER kanye ne-TRACK ROLLER ziye zaqiniswa ukuqina kwemvamisa ephakathi. I-TRACK ROLLER, i-TOP ROLLER kanye ne-IDLER zivalwe ngezimbozo zikawoyela ezintantayo futhi zigcotshwe ngamafutha. Lapho zijikeleza, umkhawulo owodwa wendandatho yesimbozo esintantayo awuhambi, kanti omunye umkhawulo wendandatho yesimbozo esintantayo ujikeleza nesondo, ngosizo lokucindezeleka kwendandatho ye-O, ukuze ukucindezela kobuso bendandatho yesimbozo esintantayo ezimbili, kufinyelelwe uphawu. Uphawu lukawoyela oluntantayo luthembekile, ngokuvamile esikhathini sokulungisa aludingi ukugcwalisa uphethiloli we-track roller, i-IDLER kanye ne-TRACK ROLLER.

(3)I-ROLLER ENGAPHEZULU

I-TOP ROLLER iyilungu eliyinhloko lamandla ethrekhi, futhi izinkinga zokuguguleka namandla ziyabonakala uma usebenza ngaphansi kwezimo ezinamatshe namanzi. I-TOP ROLLER iyinsimbi ye-carbon alloy ephezulu ene-medium frequency quenching ebusweni, enokumelana okuhle kakhulu nokuguguleka.

(4)Ukucindezeleka kwamathrekhi(ngemizila yerabha neyensimbi)

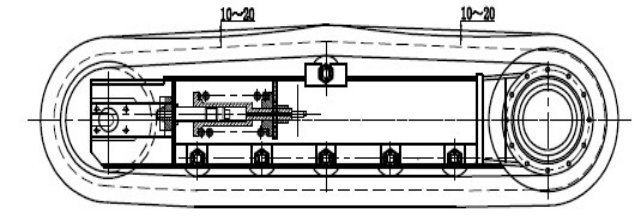

Ukuphila komzila weketanga kuvame ukuncika ezingeni lokucindezeleka komzila nokuthi ukulungiswa kunengqondo yini, ngakho hlola izinga lokucindezeleka komzila njalo emahoreni angu-30. Izinga lokuqina komzila: qala uhlanze umzila, uphakamise umzila wensimbi noma umzila werabha ngesandla, bese ukuphakama kokuphakamisa okungaba ngu-10cm kubhekwa njengokujwayelekile. Uma ulungisa ukuqina komzila, ungakulungisi ukhululeke kakhulu noma uqine kakhulu, kumele kube phakathi, umzila uqine kakhulu, kuzothinta isivinini sokuhamba kanye namandla okuhamba, futhi kuzokwandisa ukuguguleka phakathi kwengxenye ngayinye, uma ulungiswa ukhululekile kakhulu, umzila okhululekile uzobangela ukuguguleka okukhulu esondweni lokushayela kanye nesondo leketanga lokudonsa. Idivayisi yokucindezela umzila iqukethe indlela yokucindezela nokulungisa i-hydraulic.

Umfanekiso 2 Umdwebo weskimu wokucindezela ithrekhi (indlela yokulungisa iwuhlobo lokulungisa intambo)

(4.1) Inqubo ethile yokusebenza kwendlela yokulungisa intambo: ngemva kokuvula i-nameplate emqamelweni oyinhloko ohlangothini olungaphandle lwethrekhi, sebenzisa isikrufu esivulekile ukuze ujikeleze isikulufu sokulungisa esinama-hexagonal bese ubona indlela yokunyakaza kwe-IDLER, lapho i-IDLER iqhubekela phambili ukuze ithrekhi iqiniswe kanye ne-IDLER iqhubekela emuva ukuze ithrekhi inciphe.

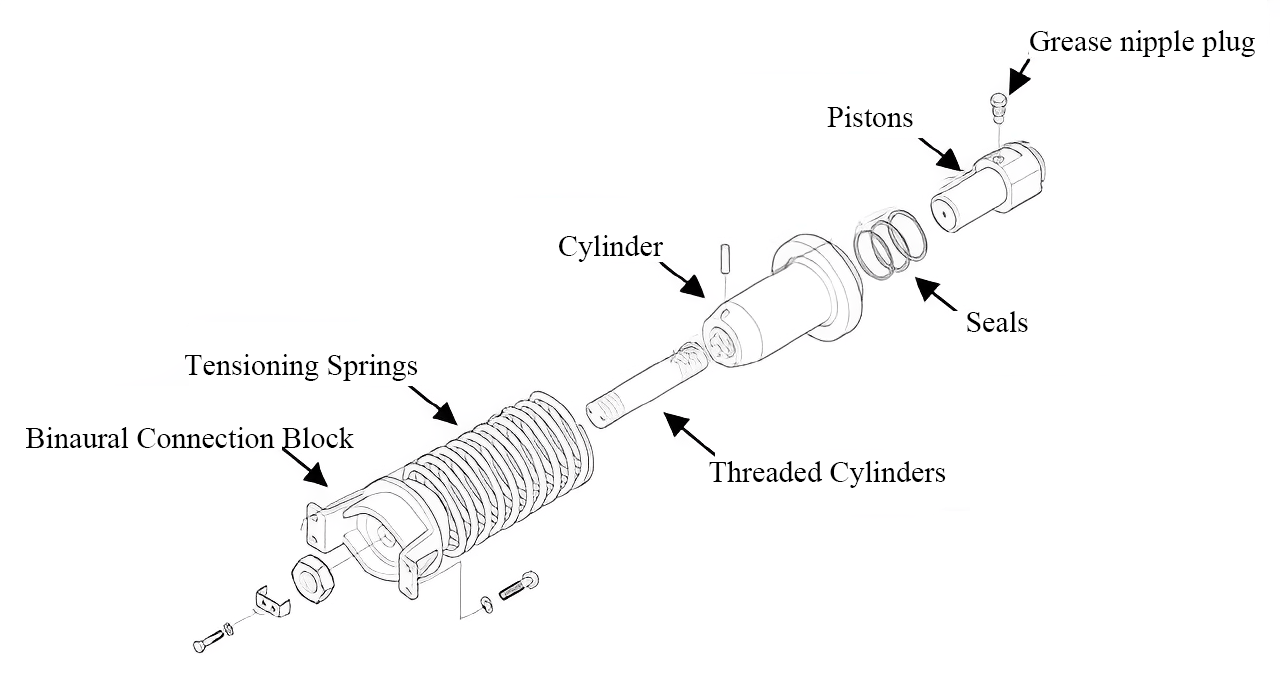

(4.2) Inqubo ethile yokusebenza yokuqinisa i-hydraulic: ngemva kokuvula i-nameplate emqameni oyinhloko ohlangothini lwangaphandle lwethrekhi, i-check valve grease nipple ingabonakala, uma ukuphakama kokuphakamisa ithrekhi kungu->3cm, sebenzisa i-grease gun ukuze ubambe i-check valve grease nipple ukuze ugcwalise uphethiloli. Uma ukuphakama kokuphakamisa kwethrekhi kungu-<3cm, khulula i-grease nipple ibe ngamajika angu-1-2, futhi ithrekhi izoncipha uma kukhona ukugcwala kwamafutha, sebenzisa indlela okukhulunywe ngayo ngaphambilini ukuze uphakamise ithrekhi ngesandla ukuze uhlole ukukhululeka nokuqina kwethrekhi (enamathiselwe ngomfanekiso olandelayo ukuze uqinise i-grease nipple). Okokuqala khulula i-cylinder grease nipple ukujika okungu-1 kuya ku-2, i-cylinder cylinder grease ikhishwe, i-cylinder rod ihoxiswe. Bese uqinisa i-grease nipple, bese ufaka i-grease entsha, hlola ukuthi ubuso be-cylinder rod abujwayelekile yini, futhi uma kudingeka, faka i-grease entongeni yesilinda, bese uqedela ukugcinwa kwe-rise and strength cylinder (isithombe 3 esinamathiselwe).

(Isithombe 3 Umdwebo weskimu wokuqinisa kwe-hydraulic (uhlobo lokulungisa ukuqinisa kwe-hydraulic)

(4.3): uma i-chassis isetshenziswa njalo, engeza uwoyela kanye njalo ezinyangeni eziyisithupha noma ngaphezulu, bese ufaka uwoyela wegiya ongu-90# ku-TOP ROLLER kanye ne-track roller (engeza uwoyela ngembobo yepulaki kawoyela emzimbeni wesondo).

(5)Sicela ubheke incwadi yemiyalelo yokusebenzisa ibhokisi lokunciphisa elihambayo (elinamathiselwe).

(6)Sicela ugcine i-chassis assembly ihlanzekile, uma ingasetshenziswa, sicela uyibeke endaweni epholile neyomile, ugweme ukukhanya kwelanga nemvula. Ngesikhathi sokusebenza, hlola ukubukeka kwe-chassis yokukhasa nsuku zonke, futhi qhubeka uhlola amabhawodi okuxhuma esondweni lokushayela kanye nebhokisi lamagiya nsuku zonke, bese uwaqinisa ngesikhathi uma etholakala ekhululekile. Ngesikhathi sokusebenzisa, sicela unake ijubane lomshini, isivinini esiphansi, ungasheshi ngokweqile futhi ulayishe ngokweqile. Ngemva kokuba amanzi olwandle noma amanzi e-alkaline evele, wageze ngokushesha ngamanzi ahlanzekile. Ngemva kokusebenzisa endaweni yokwakha, hlanza ngokushesha ukuze ususe udaka, hlanza usimende, ugcine uhlanzekile!!!!

Ucingo:

Ucingo: I-imeyili:

I-imeyili: