Zhenjiang Yijiang Machinery Co.,Ltd

Crawler Undercarriage Maintenance Manual

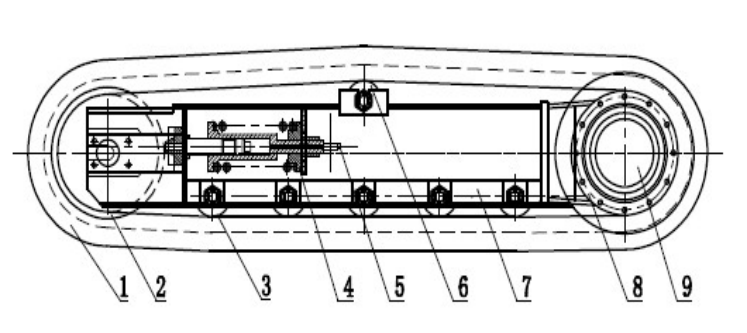

1. track assembly 2. IDLER 3. track roller 4. tensioning device 5. thread adjustment mechanism 6. TOP ROLLER 7. track frame 8. drive wheel 9. travelling speed reducer (common name: motor speed reducer box)

The left and right tracks are driven by the left and right travelling hydraulic motors to drive the left and right travelling gearboxes respectively, driving the tracks to travel.

(1)Track assemblies (including steel track assemblies and rubber track assemblies)

1:1 Steel track assembly is made of high strength alloy steel forged by special heat treatment process, featuring strong wear resistance, long service life and high strength.

1:2 Rubber Track Assembly, Rubber track is a ring-shaped rubber belt made of rubber compounded with metal or fibre material. Precautions for use: the machine should be avoided to start or turn quickly in sharp and protruding places. Do not allow the rubber surface to come into contact with oil, wipe off the oil as soon as it is present, and avoid the tracks coming into contact with other parts on the machine, especially the inner edges. Do not use badly worn drive wheels, it will damage the iron teeth of the tracks. When the machine is not working for a long time, the rubber tracks should be removed and cleaned of dirt and other things, avoiding sun and rain. As they are rubber products, rubber tracks are generally used in temperatures ranging from -25° to 55°.

1:3 For use in special industries, such as those operating under seawater, where various salts are dissolved and various ions are present, resulting in oxidising and reducing properties. It is extremely harmful to rubber or steel. At present, under the premise of no corresponding data support, rubber tracks warranty half a year or 500 hours, and then subsequently adjusted according to the use of the situation. It should be emphasised that, regardless of whether the chassis is rubber or steel, it should be rinsed out with fresh water promptly after leaving seawater!

(2) IDLER, TRACK ROLLER

The working conditions of the IDLER and TRACK ROLLER are very harsh, it not only directly bear the weight of the machine, but also bear the violent impact load from the base plate. Sometimes a TRACK ROLLER has to carry half of the weight of the whole machine. Due to the low installation position of the TRACK ROLLER, it has been in the gravel and magma for a long time, and is subject to serious wear and tear. Therefore, the working surfaces of the track roller, IDLER and TRACK ROLLER have been hardened by medium-frequency hardening. The TRACK ROLLER, TOP ROLLER and IDLER are sealed by floating oil seals and lubricated by grease. When rotating, one end of the floating seal ring does not move, and the other end of the floating seal ring rotates with the wheel, with the help of the tension of the O-ring, so that the two floating seal ring end surface compression, to achieve the seal. The floating oil seal is reliable, usually in an overhaul period does not need to refuel the track roller, IDLER and TRACK ROLLER.

(3) TOP ROLLER

The TOP ROLLER is the main force member of the track, and the wear and strength problems are prominent when working under rocky and watery conditions. The TOP ROLLER is high carbon alloy steel with medium frequency quenching on the surface, which has excellent wear resistance.

(4) Tensioning of tracks (for rubber and steel tracks)

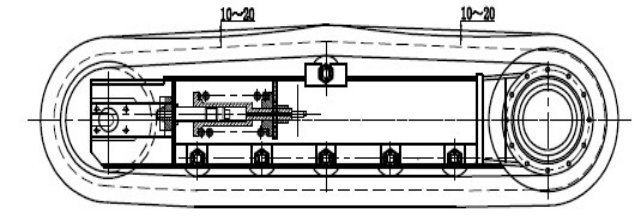

The life of the chain track often depends on the degree of tension of the track and whether the adjustment is reasonable, so check the degree of tension of the track every 30 hours. The standard of track tightness: first clean the track, lift the steel track or rubber track by hand, and the lifting height of about 10cm is regarded as normal. When adjusting the track tightness, don’t adjust it too loose or too tight, it must be moderate, the track is too tight, it will affect the travelling speed and travelling power, and it will increase the wear and tear between each part, if it is adjusted too loosely, the loose track will cause a lot of wear and tear in the driving wheel and the drag chain wheel. The track tensioning device consists of hydraulic tensioning and adjusting mechanism.

Fig. 2 Schematic diagram of track tensioning (the adjustment mechanism is of the thread adjustment type)

(4.1) Specific operation procedure of the thread adjustment mechanism: after opening the nameplate on the main beam on the outer side of the track, use an open-end wrench to rotate the hexagonal adjusting screw and observe the direction of movement of the IDLER, with the IDLER moving forward for the track to be tightened and the IDLER moving backward for the track to be slackened.

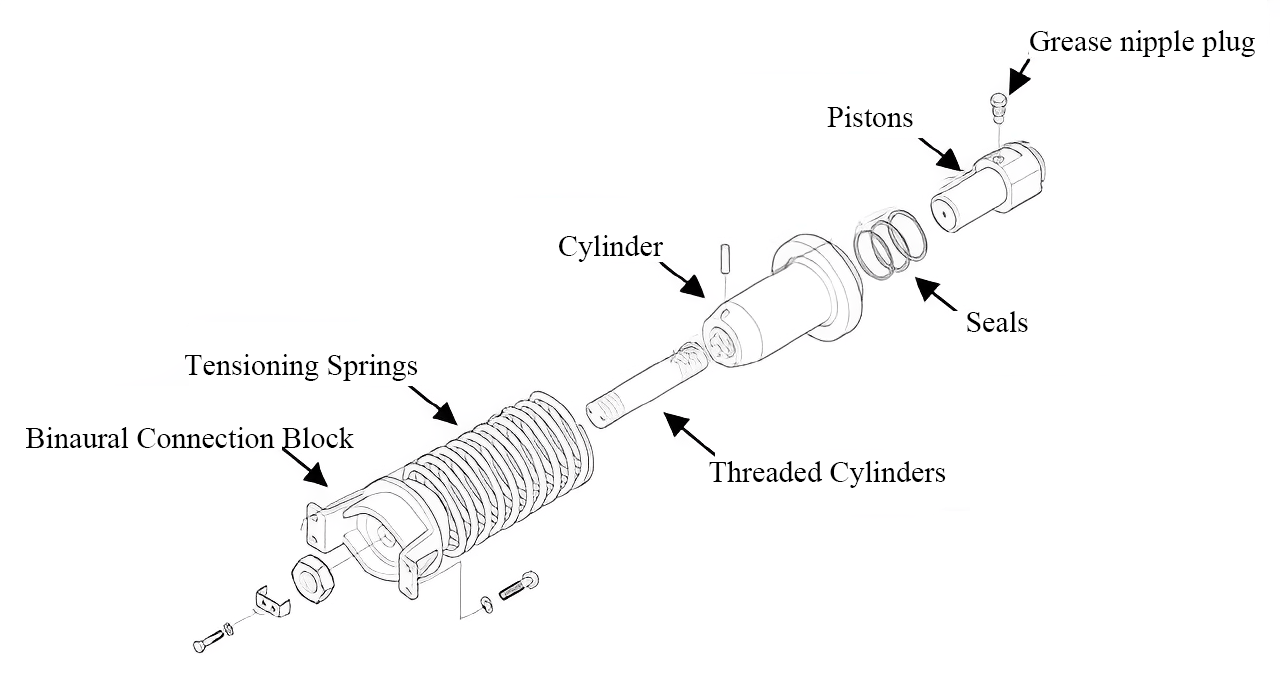

(4.2) Specific operation procedure of hydraulic tightening: after opening the nameplate on the main beam on the outer side of the track, the check valve grease nipple can be seen, if the height of the track lifting is >3cm, use the grease gun to hold the check valve grease nipple for refuelling. If the lifting height of the track is <3cm, loosen the grease nipple to 1-2 turns, and the track will be slackened if there is overflow of grease, use the method mentioned before to lift the track by hand to check the loosening and tightening of the track (attached with the following figure to tighten the grease nipple). First loosen the cylinder grease nipple 1 to 2 turns, the cylinder cylinder grease discharge, the cylinder rod retracted. Then tighten the grease nipple, then add new grease, check whether the surface of the cylinder rod is abnormal, and if necessary, apply grease on the cylinder rod, and then complete the maintenance of the rise and tighten cylinder (attached figure 3).

(Figure 3 Schematic diagram of hydraulic tightening (hydraulic tightening adjustment type)

(4.3): if the chassis is used frequently, add oil once every six months or so, and add 90# gear oil to the TOP ROLLER and the track roller (add oil through the oil plug hole on the wheel body).

(5)Please refer to the instruction manual for the use of the travelling reduction gearbox (attached).

(6)Please keep the chassis assembly clean, when not in use, please place it in a cool and dry place, avoid sunshine and rain. During the working period, check the appearance of the crawler chassis daily, and keep checking the connecting bolts at the driving wheel and gearbox every day, and tighten them in time if they are found to be loose. During the use, please pay attention to the speed of the machine, low speed, do not over speed and overload. After seawater or alkaline water comes up, immediately rinse it with clean water. After use on the construction site, immediately rinse to clear the silt, clear the cement, keep clean!!!!

Post time: Feb-08-2024